The yard's signature "Goliath" crane

Click on the photos for a larger version; click on links in the text for more infomation.

Thomas Augustus Watson is best known as Alexander

Graham Bell's assistant, but to shipbuilders he is important

for an entirely different reason.

Thomas Augustus Watson is best known as Alexander

Graham Bell's assistant, but to shipbuilders he is important

for an entirely different reason.

Watson left the Bell Co. in 1881, then spent a year traveling, and two

years farming at East Braintree, Massachusetts. In 1884 he founded the

Fore River Engine Company, initially located in this small house in East

Braintree, near the Fore River. This tiny business, with only one

employee, was the humble start of what would soon become one of the

nation's largest shipyards.

In 1900 the company launched the lightship Diamond

Shoals (left), the first all-steel vessel built on Boston's South Shore,

and the destroyer USS Lawrence, the yard's first naval contract.

In 1900 the company launched the lightship Diamond

Shoals (left), the first all-steel vessel built on Boston's South Shore,

and the destroyer USS Lawrence, the yard's first naval contract.

Another major event in 1900 was the groundbreaking for the company's new

shipyard, two miles

downriver from the old site.

The new location, in Quincy, MA, was a good

location for a shipyard - near the

major seaport of Boston, convenient to rail and sea transportation,

possessing both a sheltered, riverside location, and deepwater access to

the ocean, and with plenty of space to expand. One drawback was the

wooden bridge across the river's mouth, seen in this view of the

groundbreaking ceremony, which kept large ships out of the river. Watson

prevailed upon the local governments to fund a new bridge - and they hired

him to build it!

Another major event in 1900 was the groundbreaking for the company's new

shipyard, two miles

downriver from the old site.

The new location, in Quincy, MA, was a good

location for a shipyard - near the

major seaport of Boston, convenient to rail and sea transportation,

possessing both a sheltered, riverside location, and deepwater access to

the ocean, and with plenty of space to expand. One drawback was the

wooden bridge across the river's mouth, seen in this view of the

groundbreaking ceremony, which kept large ships out of the river. Watson

prevailed upon the local governments to fund a new bridge - and they hired

him to build it!

The view at left shows the company's facilities circa 1902. In this year the

cruiser Des Moines was launched from the new yard; she was the

largest vessel yet built by the company. Another 1902 launching was the

giant seven-masted schooner Thomas W. Lawson, the only ship

of her type ever constructed.

By this time the new yard, now known as the

Fore River Ship & Engine Co., was a busy and growing enterprise, soon to

have an even bigger role in the shipbuilding industry.

The view at left shows the company's facilities circa 1902. In this year the

cruiser Des Moines was launched from the new yard; she was the

largest vessel yet built by the company. Another 1902 launching was the

giant seven-masted schooner Thomas W. Lawson, the only ship

of her type ever constructed.

By this time the new yard, now known as the

Fore River Ship & Engine Co., was a busy and growing enterprise, soon to

have an even bigger role in the shipbuilding industry.

In the years leading up to WWI, the Fore River yard constructed a wide

variety of ships, including cruisers, destroyers, submarines, four

battleships, and numerous merchant ships.

In the years leading up to WWI, the Fore River yard constructed a wide

variety of ships, including cruisers, destroyers, submarines, four

battleships, and numerous merchant ships.

To accommodate these contracts the yard continued to expand; at left is a

view of the yard circa 1910, apparently from the large crane on the

fitting-out pier. One of the four battleship contracts in the prewar

years was for Rivadavia, built for Argentina (at right); she was

the first Fore River vessel built for a foreign power. Bethlehem Steel

had the contract to supply the steel for this vessel, and many others

built at the yard. Due to concerns about Fore River's ability to

complete the Rivadavia on budget, Bethlehem Steel purchased the

shipyard in 1913, thereby protecting their interest in the contract, and

securing a greater role in the shipbuilding industry.

To accommodate these contracts the yard continued to expand; at left is a

view of the yard circa 1910, apparently from the large crane on the

fitting-out pier. One of the four battleship contracts in the prewar

years was for Rivadavia, built for Argentina (at right); she was

the first Fore River vessel built for a foreign power. Bethlehem Steel

had the contract to supply the steel for this vessel, and many others

built at the yard. Due to concerns about Fore River's ability to

complete the Rivadavia on budget, Bethlehem Steel purchased the

shipyard in 1913, thereby protecting their interest in the contract, and

securing a greater role in the shipbuilding industry.

Now known as Bethlehem Fore River, and later as Bethlehem Quincy, Watson's

yard continued to grow and prosper. As war clouds gathered in Europe, the

need for ships - especially naval vessels - increased. Bethlehem

constructed an additional shipyard in the nearby Squantum section of

Quincy, intended specificially for mass-production of destroyers, while

also expanding the Fore River yard; wartime employment reached 15,000. At

right is a view of the Fore River yard in early 1919, while WWI

construction programs were still ongoing; at least five "flush deck"

destroyers are visible along the waterfront. Together, the Fore River and

Squantum yards turned in an admirable performance during the war, building

18 destroyers, 10 submarines, and 6 merchant ships in 1918 alone. In all,

the yards built 71 destroyers during the war - more than the total output

of all other US shipyards combined! One of the war-built destroyers was

USS Reid (DD 292) (at left, clearing the Fore River bridge), built

in a record-setting time of 45 1/2 days. Following WWI the Squantum yard

was closed, later becoming part of a Naval Air Station; decades later the

site was redeveloped as a residential community.

Now known as Bethlehem Fore River, and later as Bethlehem Quincy, Watson's

yard continued to grow and prosper. As war clouds gathered in Europe, the

need for ships - especially naval vessels - increased. Bethlehem

constructed an additional shipyard in the nearby Squantum section of

Quincy, intended specificially for mass-production of destroyers, while

also expanding the Fore River yard; wartime employment reached 15,000. At

right is a view of the Fore River yard in early 1919, while WWI

construction programs were still ongoing; at least five "flush deck"

destroyers are visible along the waterfront. Together, the Fore River and

Squantum yards turned in an admirable performance during the war, building

18 destroyers, 10 submarines, and 6 merchant ships in 1918 alone. In all,

the yards built 71 destroyers during the war - more than the total output

of all other US shipyards combined! One of the war-built destroyers was

USS Reid (DD 292) (at left, clearing the Fore River bridge), built

in a record-setting time of 45 1/2 days. Following WWI the Squantum yard

was closed, later becoming part of a Naval Air Station; decades later the

site was redeveloped as a residential community.

Between the World Wars Quincy maintained a steady stream of merchant

vessels and warships - cruisers, submarines, destroyers, and aircraft

carriers. One of the largest and most important ships of the 'tween-wars

years was the big aircraft carrier USS Lexington (CV 2), the "Queen

of the Flattops", converted from a cancelled battlecruiser and delivered

in 1927. As the first non-experimental carriers in the US fleet, she and

her sister Saratoga played a vital role in building the US carrier

forces that were so vital to naval warfare during WWII. Lexington

was a source of great pride for Quincy shipbuilders, and her loss early in

WWII was deeply felt at the yard.

Between the World Wars Quincy maintained a steady stream of merchant

vessels and warships - cruisers, submarines, destroyers, and aircraft

carriers. One of the largest and most important ships of the 'tween-wars

years was the big aircraft carrier USS Lexington (CV 2), the "Queen

of the Flattops", converted from a cancelled battlecruiser and delivered

in 1927. As the first non-experimental carriers in the US fleet, she and

her sister Saratoga played a vital role in building the US carrier

forces that were so vital to naval warfare during WWII. Lexington

was a source of great pride for Quincy shipbuilders, and her loss early in

WWII was deeply felt at the yard.

Starting in the late 1930's Quincy once again stepped up production to

meet the wartime challenge. By 1941 employment had already reached

17,000, and facilities were being rapidly expanded to accommodate growing

shipbuilding requirements. The yard turned out numerous aircraft

carriers, cruisers, destroyers, and the battleship USS

Massachusetts during the war. Aircraft carriers included USS

Lexington (CV 16) (at left, launching), named in honor of the

previous carrier Lexington, and the cruiser USS Canberra (CA

70) (at right, clearing the new Fore River bridge), honoring an Australian

cruiser sunk while operating with US forces early in the war.

Starting in the late 1930's Quincy once again stepped up production to

meet the wartime challenge. By 1941 employment had already reached

17,000, and facilities were being rapidly expanded to accommodate growing

shipbuilding requirements. The yard turned out numerous aircraft

carriers, cruisers, destroyers, and the battleship USS

Massachusetts during the war. Aircraft carriers included USS

Lexington (CV 16) (at left, launching), named in honor of the

previous carrier Lexington, and the cruiser USS Canberra (CA

70) (at right, clearing the new Fore River bridge), honoring an Australian

cruiser sunk while operating with US forces early in the war.

Once again an additional mass-production yard was needed to meet wartime

shipbuilding needs. This yard, located in nearby Hingham, built destroyer

escorts and landing ships (LST, LCI(L)) in great numbers. These smaller,

relatively simple ships played a vital role in the US victory, and were

built in record time. One DE was launched just 23 days after keel-laying,

and in one 50-hour span a total of 5 LSTs were delivered. Combined

employment at the Hingham and Quincy yards reached 32,000 - more than

double the WWI peak. The Hingham yard closed down after the war, and was

eventually sold off and used for various industrial purposes. The Hingham

shipyard property is now scheduled to be redeveloped as a residential

community.

Once again an additional mass-production yard was needed to meet wartime

shipbuilding needs. This yard, located in nearby Hingham, built destroyer

escorts and landing ships (LST, LCI(L)) in great numbers. These smaller,

relatively simple ships played a vital role in the US victory, and were

built in record time. One DE was launched just 23 days after keel-laying,

and in one 50-hour span a total of 5 LSTs were delivered. Combined

employment at the Hingham and Quincy yards reached 32,000 - more than

double the WWI peak. The Hingham yard closed down after the war, and was

eventually sold off and used for various industrial purposes. The Hingham

shipyard property is now scheduled to be redeveloped as a residential

community.

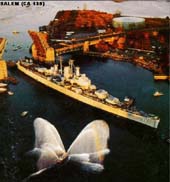

The postwar years saw a wide variety of shipbuilding at Quincy.

Naval shipbuilding ranged from ships ordered under the wartime

shipbuilding programs, such as the cruiser

USS Salem (CA 139)

(left), to the hi-tech nuclear-powered missile ships USS

Bainbridge (DLGN 25) and USS Long Beach (CGN 9) (right), the

world's first nuclear powered surface combatant. Other

naval construction included destroyers, frigates, and a tanker.

Commercial projects included the liner Independence (completed in

1950 and still in service today), and the supertanker Manhattan,

famous for her voyage through the Northwest Passage. Unfortunately, the

prosperity could not last; Bethlehem closed the yard in 1963.

The postwar years saw a wide variety of shipbuilding at Quincy.

Naval shipbuilding ranged from ships ordered under the wartime

shipbuilding programs, such as the cruiser

USS Salem (CA 139)

(left), to the hi-tech nuclear-powered missile ships USS

Bainbridge (DLGN 25) and USS Long Beach (CGN 9) (right), the

world's first nuclear powered surface combatant. Other

naval construction included destroyers, frigates, and a tanker.

Commercial projects included the liner Independence (completed in

1950 and still in service today), and the supertanker Manhattan,

famous for her voyage through the Northwest Passage. Unfortunately, the

prosperity could not last; Bethlehem closed the yard in 1963.

The Quincy shipyard was purchased by General Dynamics Corporation in 1964,

becoming that company's Quincy Shipbuilding Division, and a "sister"

division to Electric Boat. Within a few years General Dynamics invested in

major modernizations of the shipyard.

The Quincy shipyard was purchased by General Dynamics Corporation in 1964,

becoming that company's Quincy Shipbuilding Division, and a "sister"

division to Electric Boat. Within a few years General Dynamics invested in

major modernizations of the shipyard.

Modernizaton included replacement of the conventional sliding ways with

modern

construction basins, implementation of a highly automated production

process, and extensive use of "pre-outfit" construction techniques. At

left is an automated plate stiffener, part of the semi-automated steel

fabrication process. At right, the 1,200 ton capacity "Goliath" crane

lowers the entire bow section of a LNG tanker into place. Preoutift or

"modular" construction allows entire pieces of the ship to be built and

outfitted with all their equipment in a shop or assembly area away from

the building slip, where work can be done most efficiently. The pieces,

weighing anything from 150 tons to over 1,000 tons, are then installed on

the ship by cranes. The 1,200 ton Goliath crane, part of General

Dynamics' modernization of the facility, and largest shipbuilding crane on

the continent, was a key to the use of very large preoutfit units, such as

entire deckhouses, bows, and sterns.

Modernizaton included replacement of the conventional sliding ways with

modern

construction basins, implementation of a highly automated production

process, and extensive use of "pre-outfit" construction techniques. At

left is an automated plate stiffener, part of the semi-automated steel

fabrication process. At right, the 1,200 ton capacity "Goliath" crane

lowers the entire bow section of a LNG tanker into place. Preoutift or

"modular" construction allows entire pieces of the ship to be built and

outfitted with all their equipment in a shop or assembly area away from

the building slip, where work can be done most efficiently. The pieces,

weighing anything from 150 tons to over 1,000 tons, are then installed on

the ship by cranes. The 1,200 ton Goliath crane, part of General

Dynamics' modernization of the facility, and largest shipbuilding crane on

the continent, was a key to the use of very large preoutfit units, such as

entire deckhouses, bows, and sterns.

Under General Dynamics ownership, Quincy concentrated on large merchant

and naval vessels, well suited to semi-automated and preoutfit

construction techniques.

Under General Dynamics ownership, Quincy concentrated on large merchant

and naval vessels, well suited to semi-automated and preoutfit

construction techniques.

Naval construction included replenishment oilers, ammunition ships,

submarine tenders, and amphibious ships such as USS Mount Vernon

(LSD 39), at left. Quincy also constructed several nuclear powered

submarines before that work was consolidated at General Dynamics' Electric

Boat Division. Merchant construction included large, but relatively

complex ships, such as SeaBee barge carriers, roll-on/roll-off vehicle

ships, and the innovative coal-fired self-unloading collier Energy

Independence (right), designed to haul coal to New England power

plants. Quincy also did extensive overhaul, modernization, and conversion

work for both military and commercial customers, including the complete

reconstruction of the cable layer USNS Neptune (T-ARC 2), and the

rebuilding of the tanker Overseas Boston.

Naval construction included replenishment oilers, ammunition ships,

submarine tenders, and amphibious ships such as USS Mount Vernon

(LSD 39), at left. Quincy also constructed several nuclear powered

submarines before that work was consolidated at General Dynamics' Electric

Boat Division. Merchant construction included large, but relatively

complex ships, such as SeaBee barge carriers, roll-on/roll-off vehicle

ships, and the innovative coal-fired self-unloading collier Energy

Independence (right), designed to haul coal to New England power

plants. Quincy also did extensive overhaul, modernization, and conversion

work for both military and commercial customers, including the complete

reconstruction of the cable layer USNS Neptune (T-ARC 2), and the

rebuilding of the tanker Overseas Boston.

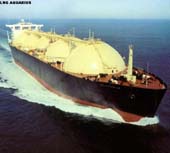

The major constructon program at Quincy from the mid-1970's to the early

1980's was the construction of 10 liquified natural gas (LNG) tankers.

These massive ships, 936 feet long and displacing as much as a large

aircraft carrier, transported 125,000 cubic meters of LNG in five 120 foot

diameter cargo spheres. Preoutfit and "modular" construction were

extensively employed in building the LNG tankers. The bow, stern,

midbody, and deckhouse were constructed separately, then joined together

at various stages of assembly. The huge, 750-ton cargo spheres were

constructed in a specialized facility at Charleston, South Carolina

(right), brought to Quincy on a special barge, and loaded aboard with the

Goliath crane. The complex compressor and cryogenic piping modules, and

the sphere covers, were constructed at Quincy and loaded aboard after the

spheres had been installed. The Quincybuilt LNG tankers are regarded as

highly successful ships, and remain in service today.

The major constructon program at Quincy from the mid-1970's to the early

1980's was the construction of 10 liquified natural gas (LNG) tankers.

These massive ships, 936 feet long and displacing as much as a large

aircraft carrier, transported 125,000 cubic meters of LNG in five 120 foot

diameter cargo spheres. Preoutfit and "modular" construction were

extensively employed in building the LNG tankers. The bow, stern,

midbody, and deckhouse were constructed separately, then joined together

at various stages of assembly. The huge, 750-ton cargo spheres were

constructed in a specialized facility at Charleston, South Carolina

(right), brought to Quincy on a special barge, and loaded aboard with the

Goliath crane. The complex compressor and cryogenic piping modules, and

the sphere covers, were constructed at Quincy and loaded aboard after the

spheres had been installed. The Quincybuilt LNG tankers are regarded as

highly successful ships, and remain in service today.

Quincy's major project during the early- and mid-1980's was the

construction of five Maritime Prepositioning Ships (MPS) for

the US Navy. Each of these 42,000

ton ships was designed to carry all the equipment and supplies need to

support 4,000 Marines in combat for 30 days. The cargo included not only

the Marines' vehicles, but all the equipment, supplies, stores, spare

parts, munitions, fuels, and water the troops would need. To accommodate

this cargo, each ship featured 150,000 square feet of vehicle decks, over

1.6 million gallons of cargo tank capacity (200,000 gallons gasoline,

540,000 gallons diesel fuel, 855,000 gallons jet fuel, 82,000 gallons

potable water), stowage for 433 drums of kerosene and lube oil, and space

for 490 standard cargo containers, which provided 101,000 cubic feet for

general cargo, 18,000 cubic feet for refrigerated cargo, and 230,000 cubic

feet of munitions stowage. In addition to carrying this impressive

loadout, the ships would have to put all the cargo ashore while anchored

two miles offshore in 50-knot winds, a three-knot current, and five-foot

seas. Accordingly, the ships were equipped with a stern ramp for

amphibious vehicles, five 39-ton cranes, two LCM(8) landing craft, 11

lighters, a floating pipeline system, and a special anchoring system.

Quincy's major project during the early- and mid-1980's was the

construction of five Maritime Prepositioning Ships (MPS) for

the US Navy. Each of these 42,000

ton ships was designed to carry all the equipment and supplies need to

support 4,000 Marines in combat for 30 days. The cargo included not only

the Marines' vehicles, but all the equipment, supplies, stores, spare

parts, munitions, fuels, and water the troops would need. To accommodate

this cargo, each ship featured 150,000 square feet of vehicle decks, over

1.6 million gallons of cargo tank capacity (200,000 gallons gasoline,

540,000 gallons diesel fuel, 855,000 gallons jet fuel, 82,000 gallons

potable water), stowage for 433 drums of kerosene and lube oil, and space

for 490 standard cargo containers, which provided 101,000 cubic feet for

general cargo, 18,000 cubic feet for refrigerated cargo, and 230,000 cubic

feet of munitions stowage. In addition to carrying this impressive

loadout, the ships would have to put all the cargo ashore while anchored

two miles offshore in 50-knot winds, a three-knot current, and five-foot

seas. Accordingly, the ships were equipped with a stern ramp for

amphibious vehicles, five 39-ton cranes, two LCM(8) landing craft, 11

lighters, a floating pipeline system, and a special anchoring system.

Construction of these ships, although simpler than the LNG tankers,

included one very notable feature. The massive deckhouses were

constructed and outfitted off-ship, and were lifted in place by the

Goliath crane. Weighing in at an incredible 1,120 tons, the MPS

deckhouses were the heaviest shipyard lifts ever accomplished in the US.

This heavyweight lift record still stands today. The five MPSs were

delivered in 1985-86, and are stationed in key locations around the world,

fully loaded and ready to sail for any trouble spot.

Construction of these ships, although simpler than the LNG tankers,

included one very notable feature. The massive deckhouses were

constructed and outfitted off-ship, and were lifted in place by the

Goliath crane. Weighing in at an incredible 1,120 tons, the MPS

deckhouses were the heaviest shipyard lifts ever accomplished in the US.

This heavyweight lift record still stands today. The five MPSs were

delivered in 1985-86, and are stationed in key locations around the world,

fully loaded and ready to sail for any trouble spot.

With the completion of the MPS contract in 1986, Quincy's future looked

bleak; there were simply too many shipyards and too few new ship orders.

When Quincy failed to land contracts for U.S. Lines container ships and

new survey ships for the Navy, the shipyard was doomed. The yard was

closed in 1986; the remaining employees were laid off or retired, and the

shipyard lay idle for the first time in decades. At left is a view of the

yard, taken in 1981 as the LNG program was coming to a close, showing the

facility in essentially its final form. The wet basin and two

construction basins are at left; the three assembly basins and the Goliath

crane at center, and the fitting out piers at right.

With the completion of the MPS contract in 1986, Quincy's future looked

bleak; there were simply too many shipyards and too few new ship orders.

When Quincy failed to land contracts for U.S. Lines container ships and

new survey ships for the Navy, the shipyard was doomed. The yard was

closed in 1986; the remaining employees were laid off or retired, and the

shipyard lay idle for the first time in decades. At left is a view of the

yard, taken in 1981 as the LNG program was coming to a close, showing the

facility in essentially its final form. The wet basin and two

construction basins are at left; the three assembly basins and the Goliath

crane at center, and the fitting out piers at right.

Following the closure the yard lay dormant for many years. Equipment was

sold off; parts of the facility were used for staging areas for public

works construction projects. A ship scrapping operation operated briefly

at one end of the shipyard, but soon closed down. There have been many

efforts to re-open and modernize the shipyard, but to date none has come

to fruition.

Following the closure the yard lay dormant for many years. Equipment was

sold off; parts of the facility were used for staging areas for public

works construction projects. A ship scrapping operation operated briefly

at one end of the shipyard, but soon closed down. There have been many

efforts to re-open and modernize the shipyard, but to date none has come

to fruition.

In 1994 the Quincybuilt cruiser Salem (CA

139) returned home to the Quincy yard, becoming the centerpiece of

the United States Naval & Shipbuilding Museum.

Today Salem is berthed at the same fitting-out pier where she was

completed over 50 years ago.

| Haze Gray & Underway | |||||

| Naval History Info Center | US Warship Histories - DANFS | World Navies Today | |||

| Photo Galleries | Shipbuilding | Navsource Photos | |||

| HG&UW Home | Contact Info | About the Site | Web Links | FAQs | Back |